System Overview

The Evaporative Crystallizer is a precision-engineered system that facilitates the formation of crystals from a solution by carefully managing the evaporation process. This system is pivotal in industries such as pharmaceuticals, chemicals, and food processing, where the controlled production of high-quality crystals is essential.

The system overview encompasses several key components and features. Firstly, the crystallizer is equipped with a jacketed vessel that allows for efficient heat transfer, ensuring precise control over the evaporation rate. This is complemented by a recirculation system that maintains a uniform temperature and supersaturation level within the solution, which is critical for consistent crystal growth.

Also includes a sophisticated control system that monitors parameters such as temperature, concentration, and evaporation rate. This real-time monitoring and adjustment capability is crucial for preventing crystal defects and ensuring the desired crystal size distribution.

Additionally, the system is designed with ease of cleaning and maintenance in mind, featuring detachable components and smooth interior surfaces to minimize product loss and contamination risks. The system's scalability and adaptability make it suitable for a range of production volumes, from laboratory-scale experiments to large-scale industrial production.

In summary, offers a reliable and efficient solution for controlled crystallization, with a focus on process optimization, product quality, and operational flexibility. Its design and features make it an indispensable tool in the production of a wide variety of crystalline products.

System Features

The Evaporative Crystallizer system is distinguished by several notable features that enhance its effectiveness in producing high-quality crystals:

Precise Temperature Control: The system is designed with advanced temperature control mechanisms to manage the evaporation rate and supersaturation levels, which are crucial for uniform and defect-free crystal growth.

Efficient Evaporation Management: The crystallizer employs a controlled evaporation process that can be fine-tuned to match the specific requirements of different substances, ensuring optimal crystallization conditions.

Agitation and Mixing Systems: To promote uniformity and prevent crystal aggregation, the crystallizer includes an agitation system that ensures consistent mixing and suspension of growing crystals within the solution.

Scalable Design: The system's components are modular, allowing it to be scaled up or down to accommodate varying production needs, from small-scale research to large commercial operations.

Easily Cleanable Surfaces: The interior surfaces of the crystallizer are smooth and designed for easy cleaning, which is essential for maintaining product quality and avoiding cross-contamination.

Real-Time Monitoring and Feedback: Advanced sensors and control systems provide real-time data on key parameters, enabling operators to make informed adjustments and maintain the crystallization process within desired specifications.

Energy Efficiency: The Evaporative Crystallizer is engineered to minimize energy consumption by optimizing the heat transfer process and reducing the need for excessive heating or cooling.

Safety Features: The system incorporates safety measures such as pressure relief valves and emergency shutdown procedures to ensure the safe operation of the crystallization process.

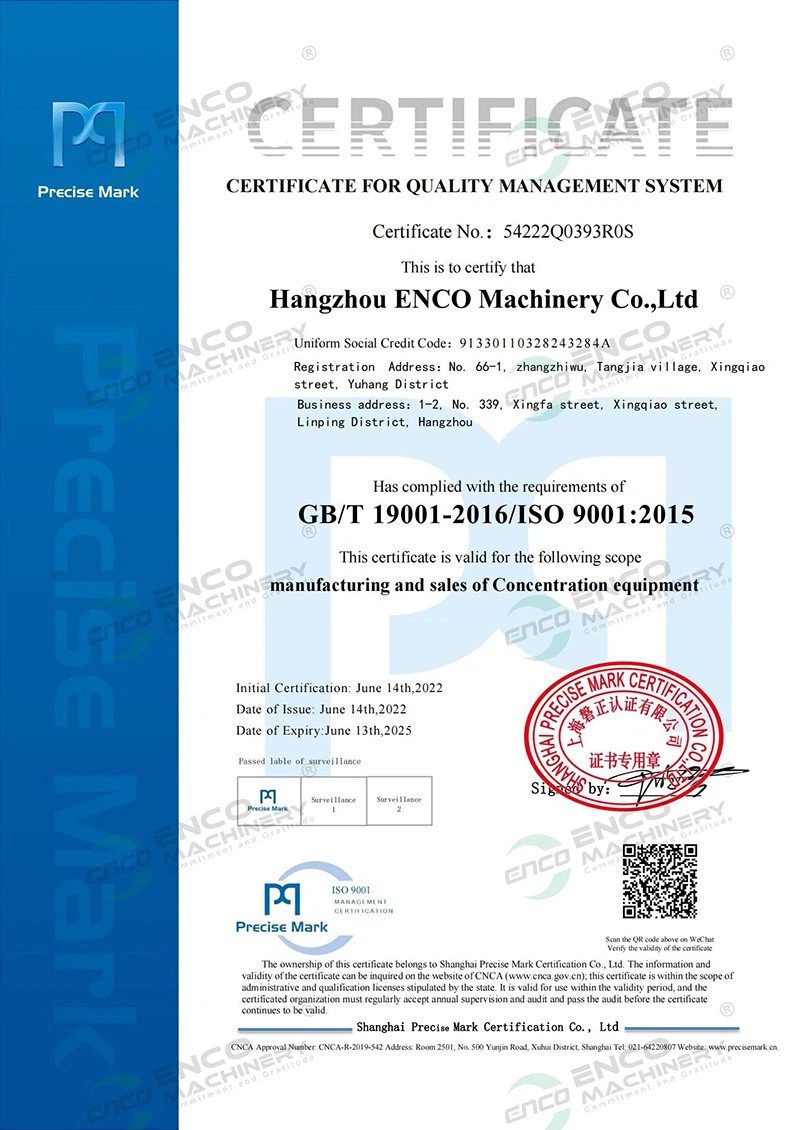

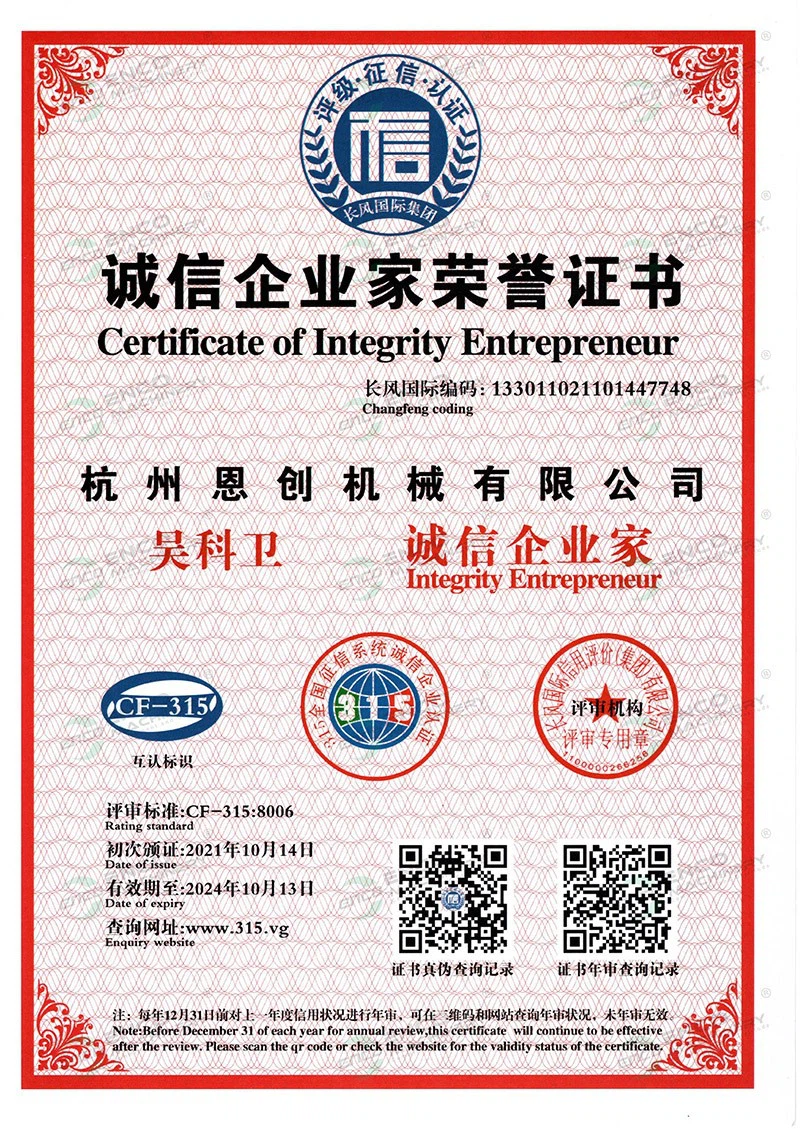

Certificate Section

Please contact us if you need any support:

Name: Kelvin

Mobile/Whatapp No.: M/W:+86 18593449637

Email: kelvin@cnenco.com