System Overview

The Triple Effect Forced Circulation Evaporator is an advanced industrial evaporation system that enhances thermal efficiency and process control through a three-stage evaporation process. This system employs forced circulation to ensure a consistent and uniform temperature across all stages, which is particularly beneficial for heat-sensitive products. The first effect directly receives heat, while the subsequent effects utilize the steam generated from the previous stage, creating a cascading heat exchange that significantly reduces energy consumption. The system is designed with a compact footprint, easy-to-clean components, and an automated control system for continuous operation and optimal performance across various applications, including food processing, pharmaceutical production, and chemical concentration.

System Features

The Triple Effect Forced Circulation Evaporator is distinguished by several key features that enhance its performance and adaptability in diverse industrial settings:

Forced Circulation Design: This feature ensures that the liquid is continuously and uniformly circulated through the evaporator, leading to efficient heat transfer and consistent product quality.

Three-Stage Evaporation: The system is divided into three effects, each operating at a progressively lower pressure, which allows for the effective use of heat from the previous stage, thereby reducing overall energy consumption.

Energy Efficiency: By utilizing the steam from one effect to heat the next, the Triple Effect Evaporator minimizes the need for additional external heating sources, resulting in significant energy savings.

Automated Control: Advanced control systems monitor and adjust the process parameters, ensuring smooth operation and maintaining the desired product specifications with minimal operator intervention.

Corrosion-Resistant Materials: The evaporator is constructed with materials that can withstand the corrosive nature of certain process fluids, prolonging the system's lifespan and reducing maintenance requirements.

Ease of Cleaning: The design of the evaporator facilitates easy disassembly and thorough cleaning, which is crucial for maintaining hygiene standards, especially in the food and pharmaceutical industries.

Scalability and Flexibility: The system's modular configuration allows for easy scaling up or down to accommodate varying production volumes and process requirements.

Low Fouling Tendency: The forced circulation minimizes the risk of fouling, which is the deposition of solids on the heat transfer surfaces, enhancing the system's operational efficiency and reducing downtime for cleaning.

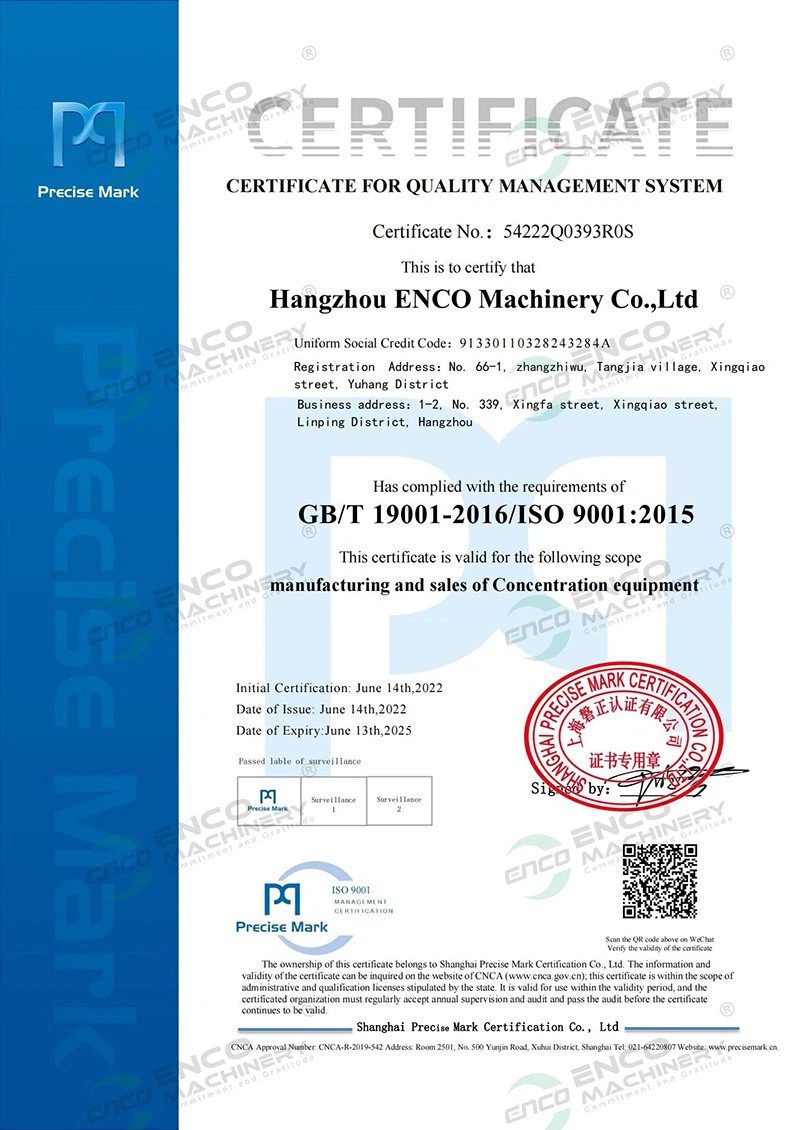

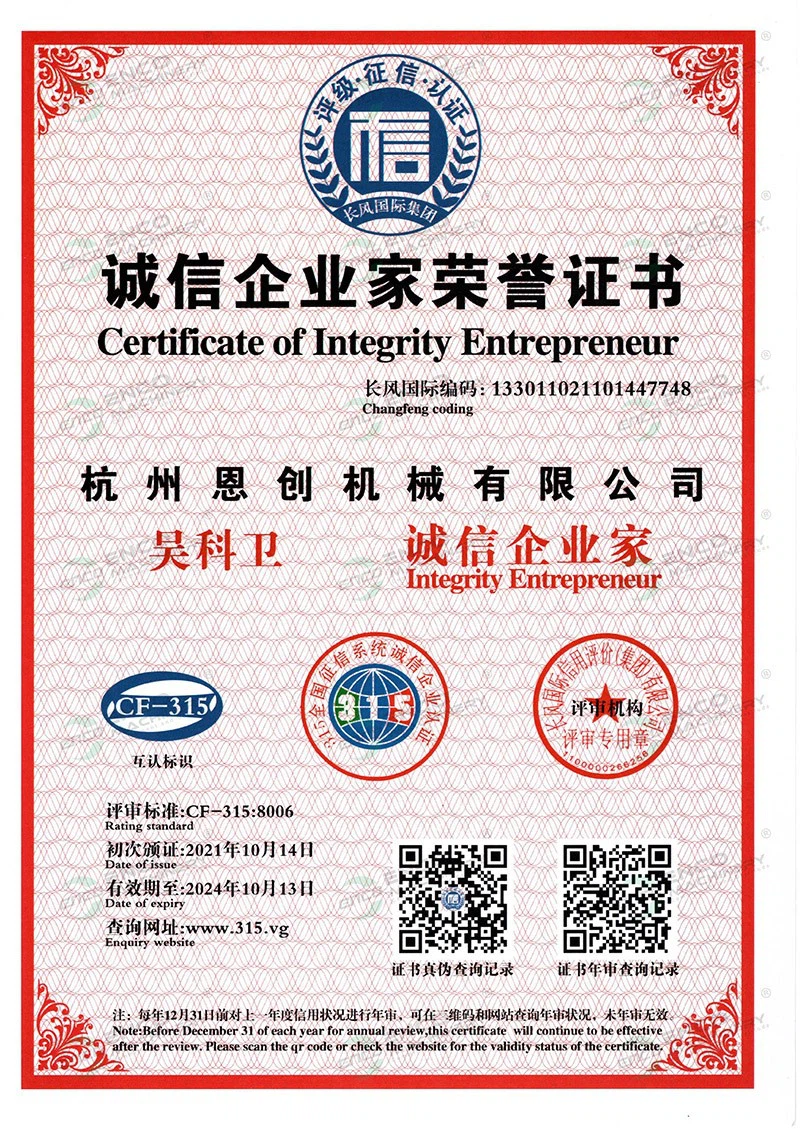

Certificate Section

Please contact us if you need any support:

Name: Kelvin

Mobile/Whatapp No.: M/W:+86 18593449637

Email: kelvin@cnenco.com